The first question you need to ask when spec’ing trucking equipment

is a simple one: What’s it going to be doing? Understanding the

application and what’s necessary for the equipment to perform properly

is the most important thing to know before making any purchasing

decision.

Take vocational suspensions, for example. They have different needs

than over-the-road suspensions because they will be tackling different

jobs, and so there are a few application factors unique to vocational

suspensions that fleet managers will need to keep in mind.

To start with, there are three different types of suspensions: air ride, leaf spring and walking beam.

Of the three, market share in the vocational space is divided

between air ride and walking beam, dependent on the particular target

segment. Many fleets tackling severe-duty applications might prefer a

walking beam suspension, for instance, while other vocational segments

will prioritize driver comfort and spec an air ride suspension.

Peter Schimunek, marketing segment manager for Western Star Trucks,

says that many vocational fleets will choose air ride suspensions

because of the stability and cushioning that they offer, which reduces

freight damage and driver fatigue. However, he notes, “some air

suspension models are best suited for highway applications, so we

recommend adhering to manufacturer recommendations for your specific

application and weight carrying capacity.”

Of course, “vocational” is a wide umbrella that covers quite a

few different types of trucks, and suspension needs will be different

for each of them.

“Capacity, stability, ride quality and durability are some of the

main considerations when spec’ing a suspension system for a vocational

truck,” says Kurt Swihart, Kenworth’s marketing director. “Vocations

with a high center of gravity, such as mixers and dump trucks, require

suspensions that provide maximum roll stability. In these applications,

we typically recommend a walking beam style suspension system. Air

suspensions are recommended when ride quality is one of the most

important considerations. While air suspensions don’t typically have the

same stability as beam style suspensions, there are several air

suspension offerings that are specifically designed for vocational

applications.”

“The needs of the vocational market are very specialized, and

each application focuses on a different aspect of the suspension as the

primary requirement,” says Sean Whitfield, director of marketing for

Hendrickson.

For example, he notes that the key attributes needed for a

suspension in concrete mixer and refuse applications are that it has the

ability to maximize carrying capacity while still preserving stability

and that it provides lower maintenance costs.

“Weight is an important factor when spec’ing a concrete mixer,”

Western Star’s Schimunek notes. “The lighter the truck, the more

concrete you can haul, which affects productivity. Choosing the right

rear suspension for the job may also result in additional weight

savings. However, mixers can get into some rough jobsites, so be sure to

spec a suspension with good articulation, ride quality and durability.

“Chassis height is also an important factor as the mixer body

must be able to fit beneath the hopper,” he adds. “A lower frame height

results in a lower center of gravity, which provides increased vehicle

stability. Customers should work closely with their dealer to spec the

right suspension for their specific job demands.”

As for dump and crane trucks, Hendrickson’s Whitfield says that

loaded stability and empty ride performance must be paired together to

survive the terrain and loading cycle of these applications.

“When the vehicle is empty and/or traveling on-road, the

equipment and driver must be protected from excessive road inputs,” he

says. “When the truck is on-site and either being loaded or being used

to lift a load, it must be supported by a suspension with high roll

stability.”

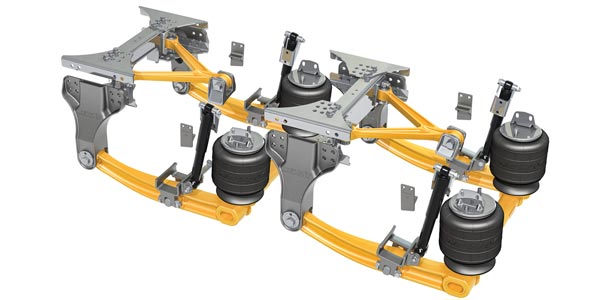

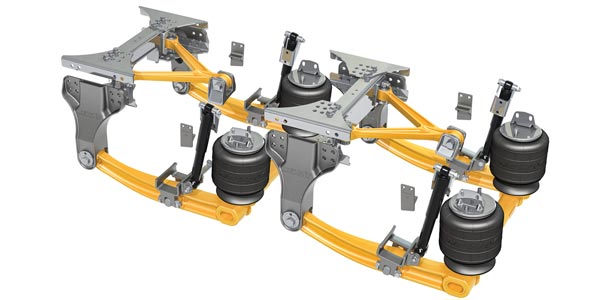

Lastly, in heavy-haul applications, Whitfield says that equipment

protection and ride quality are crucial to help ensure safe transport

of cargo and driver. This, he says, must be done without sacrificing

durability and roll stability, demanding a true vocational suspension,

and he mentions Hendrickson’s Primaax EX as an example.

Additionally, there are some factors that apply across the board for vocational suspensions, regardless of the vocation.

“Vehicle weight, axle capacity, loaded and empty CG height, creep

rating, and the operating environment are important application factors

to consider,” says Bryan Redeker, powered vehicle systems product

manager for SAF-Holland. “These factors are equally important regardless

of the type of vehicle.”

Redeker says that it is important to know if outriggers will be

present and where they are on the truck, as they may play a role in

packaging. It’s also important, he mentions, to know whether there will

be lift axles on the truck, how many, and how they will impact loading

of the suspension when they are up or down. Additionally, frame rail

spacing and package size of the lift axle assembly should be considered,

he added.

Suspension

With specific application considerations for equipment come

specific maintenance considerations, and you’ll need to keep them in

mind, especially those that are unique to vocational segments.

“Maintenance of vocational suspensions is similar to other

suspensions—visual inspection of components and bushings. For those

vocational suspensions installed with U-bolts, follow the OEM

recommended practices for checking torque,” Kenworth’s Swihart says.

“A key to maintaining a vocational suspension is following proper

inspection intervals,” Hendrickson’s Whitfield says. “For these

applications, inspections should follow the vehicle OEM and suspension

manufacturer’s service instructions, which usually list recommended

inspection intervals based on hours and/or miles of operation.”

According to Whitfield, some essential items to check for,

especially on vocational suspensions, include potential signs of

overloading such as bent or cracked steel components.

“Reviewing the transverse torque rod (TVTR) bushing wear and

replacing the TVTR when necessary is particularly important in

vocational suspensions,” he adds. “The transverse torque rod keeps the

axle aligned laterally on rubber-based suspensions and plays a large

factor in supporting the other suspension components. Once that torque

rod is fully worn, it is important that it is replaced in order to

properly maintain the suspension as a whole.”

SAF-Holland’s Redeker says that it is important to monitor

bushings, shock, air springs and fastener torque per the routine

maintenance schedule.

“These components are always important to check, regardless of

the application,” he notes, while adding, “A fleet operating in severe

vocational applications may wish to increase the frequency of checks.

Performing the initial 5,000 mile (100 hour) re-torque is critical to

suspension longevity—especially the pivot bolt connection.”

Source: Fleet Equipment by